Welding Robot Feeding

04.04.2016

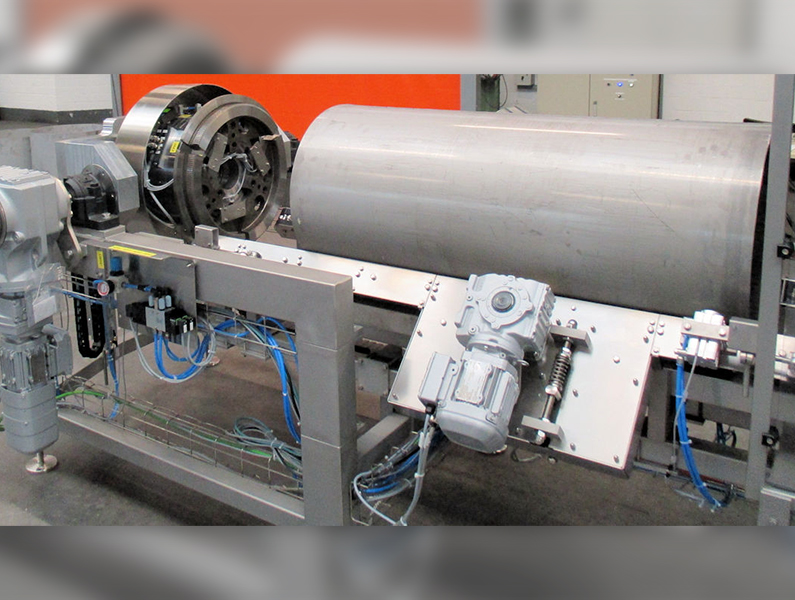

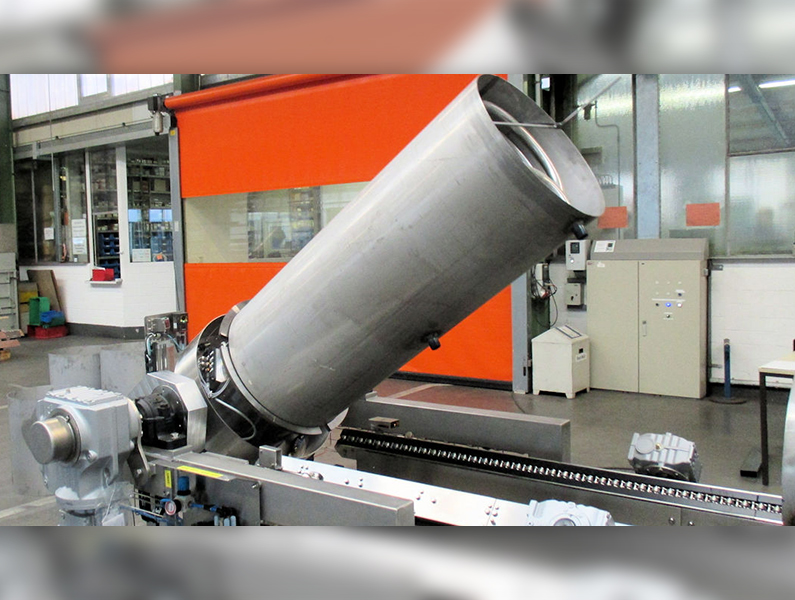

Gronemeyer has commissioned a purpose-built machine that aligns cylindrical workpieces and feeds them to a welding robot. The workpieces weigh up to 80 kg and are up to 1,400 mm long.

The workpieces are placed on our conveying system and fed individually to the alignment station. The alignment station raises the workpiece. Then it is rotated, the weld seam on the workpiece is detected and the workpiece is aligned to the desired position. During the alignment process, the workpiece is identified by a matrix code. Following this, the workpiece is released for the welding robot.

The machine has its own control system that interacts with the welding robot.