The Spiral Flow Cooler (WDK) now also with direct water cooling

28.07.2020

There has often been a demand for a continuous flow cooler in which the products are sprinkled with cold water and thus cooled more quickly. Now, on the basis of our proven WDK with circulating air cooling, we have realized a machine with water cooling. When disigning, not only the hygienic requirements were taken into account, but also exclusively corrosion-free materials were used. The drive technology is located outside the housing and the sensor technology is provided with the highest possible protection class.

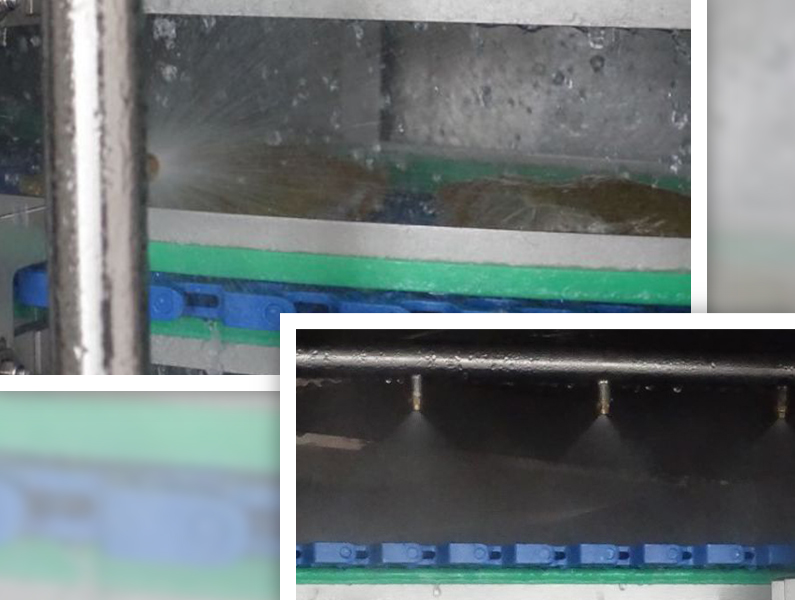

The double-tower WDK is located in a collecting basin with a volume of 4 m³. From this reservoir, cooling water is sucked in circumferentially by a pump, filtered and cooled by a plate heat exchanger. A float switch ensures the correct water quantity. Through the internal piping, the flow is evenly distributed throughout the system to approximately 350 nozzles. During the passage, the hot products are sprayed with cold water by means of nozzles arranged parallel to the chain run.

The machine housing ensures that no spray water or spray mist penetrates to the outside. It is designed with a combination of stainless steel sheet and Makrolon so that it is easy to see inside the cooler from the outside. The number and arrangement of the individual door segments has been chosen in such a way that access is possible on all sides of the system without tools.

After the moist cooling process, the product is still dried on the system mat chain by an airknife. The residual water runs back into the circuit.